Premium Glassware

All glassware are not created equal as some critical qualities can not be easily seen with the naked eye. See below for what makes our premium glassware line stand out from the crowd. Our ultimate goal is to create innovative devices and improve upon existing designs in both physical form as well as its function and ease of use. Our glassware is designed to combine artistic form with function, resulting in glassware that is both elegant to look at as well as practical to use.

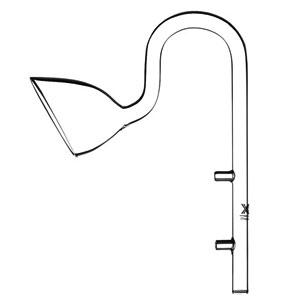

Fluxus Pipes

Glass inflow-outflow filtration pipes

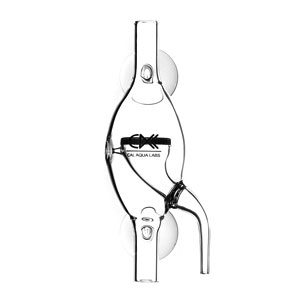

CO2 Checkers

Advanced glass CO2 Checkers

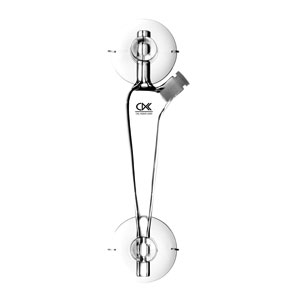

Inline diffusers

Advanced inline CO2 diffusers

Double Counters

2-in-1 CO2 bubble counters

What makes CAL AQUA LABS’ glassware unique?

All glassware are not equal. What distinguishes glassware by CAL from others can be summarized in the four major steps that every piece of CAL glassware is required to undergo:

Design

As soon as an idea for a device is conceived, our creative design team works closely with the master glass blower to finalize on a design that reveals the artistic elegance of glass as well as is practical to use. After that, several prototypes are made and tested to assess its performance, after which adjustments to the design are made. This process is repeated as required until a single optimized design has been chosen.

Materials Selection

At CAL, our stringent quality control starts early – at the material selections stage. It is here where the first round of quality control is carried out.

Not all glass is the same. Because of this, we exclusively use premium-grade borosilicate glass for our products for superior strength, durability, and clarity. Our glass tubes are from renowned glass manufacturers like Schott AG and Pyrex to assure superior quality and clarity. However, even within a single shipment, certain pieces can have minor defects or small blemishes. We carefully go through each piece within each lot by hand to select only the pieces that meet our standards.

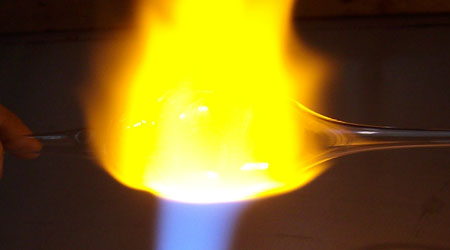

Production

Each and every piece of CAL glassware is intricately handmade by highly experienced master glass-blowers. Every curve, bend, and joints require meticulous coordination as well as absolute precision in order for the final product to meet our stringent specifications. After the pieces have been formed, they undergo not one, but two separate heat treatment steps to strengthen the glass by relieving any strain that may occur during the production process.

The second round of quality control occurs here, where each piece of our glassware is carefully inspected by hand. It is here where the pieces that meet our specifications receive the CAL AQUA LABS insignia.

Quality control

We value quality as much as we do innovation. After production, our glassware is individually inspected for the third time before being packaged. Each of our diffusers is individually tested by hand to assure that the ceramic diffuser discs perform as they should and the device functions according to specifications. Once the last round of inspection is performed, the glassware is then packaged and shipped out.